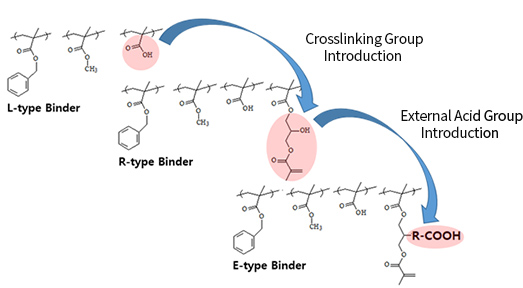

Binder

Material mixed with other components to form membranes

It requires compatibility, coating, developability, chemical resistance, and heat

| Binder | Classification | Characteristic | Product | Solvent |

|---|---|---|---|---|

| Acrylic | L-type | No Crosslinking Group | 9 Types | PGMEA 3-MBA |

| R-type | Includes Crosslinking Group | 13 Types | ||

| E-type | Includes Crosslinking Group and External Acid Group | 11 Types | ||

| Cardo | LC-type | No Crosslinking Group | 1 Type | |

| Silane | SiO | High Permeability / High Hardness |

1 Type | Alcohol |

| Epoxy | Epoxy | High Refractive | 1 Type |

| Packaging Container | Jerrycan | Drum |

|---|---|---|

| Filling Amount | 18 kg | 180 kg |

| Packaging |  |

|

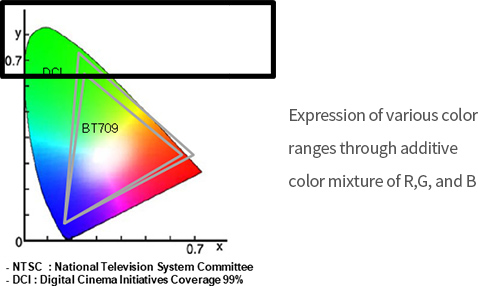

CF-PR(Color Filter Photoresist)

Negative photoresist for expression of various color ranges

| PR | Product | Solvent |

|---|---|---|

| Red | 8 Types | PGMEA 3-MBA |

| Green | 8 Types | |

| Blue | 7 Types |

| Packaging Container | Canister(18 kg) | Canister(38 kg) |

|---|---|---|

| Filling Amount | 18 kg | 38 kg |

| Packaging |  |

|

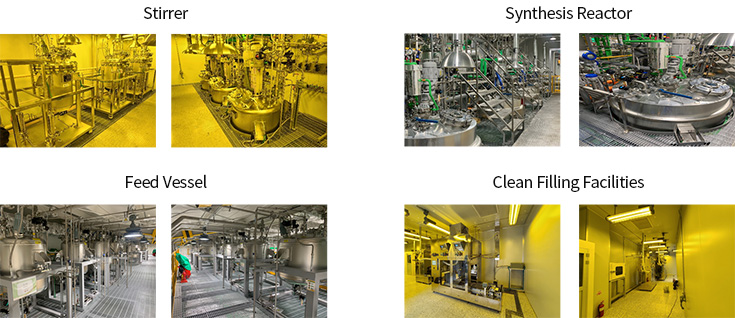

Status of Facilities

| Facilities | Main Function | Product | Installation Status |

|---|---|---|---|

| Stirrer | Formulation-Based Product Production | Color and Transparent Photoresist | 2 Types (7 Units) |

| Synthesis Reactor | Synthesis Reaction-Based Product Production | Acrylic and Silane Binder, OC | 4 Types (6 Units) |

| Feed Vessel | Automatic Raw Material Input | Liquid Raw Material | 3 Types (10 Units) |

| Clean Filling Facilities | Particle and Foreign Matter Control | All Products | 2 Types (2 Units) |